Japan Water Guard |

|

|

| |

| ●To conserve 21st century environment and water front● Save our Earth!! |

|

|

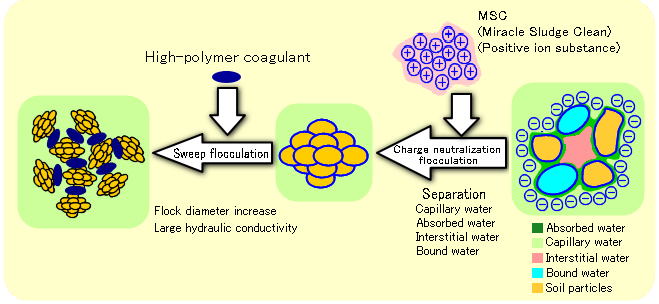

Bottom sediment treatmentMSC Method - Miracle Sludge Clean Method -Let's clean contaminated rivers, lakes/marshes, and oceans!!In rivers, lakes/marshes, and oceans, sludge has been deposited in the bottom for long time due to inflow of domestic sewage and sand. This bottom sediment (organic sediment) is the cause of water quality degradation. In the summer time, as water temperature rises, nitrogen and phosphorus increase, which leads eutrophication. Moreover, the massive outbreak of algal bloom due to photosynthesis causes water contamination and releases a strong odor.Bottom sediment treatment technology with MSC method can quickly and economically improve a large amount of the bottom sediment to good quality soil by its large flocculation ability and dehydration-separation function. Suspended solids, BOD, nitrogen, and phosphorus are removed from the water through this advanced treatment. Since MSC does not have negative impact on Eco system, it also creates suitable environment for fish and aquatic organisms. Characteristics 1. It is confirmed that treated water and soil is harmless 2. It has effects on deodorization and disinfection 3. It can reuse solid for plants because it is harmless after treatment 4. It can cut time and cost because processing speed is fast Applications ・Bottom sediment treatment for lakes/marshes, rivers, and dam ・Treatment for deposited organic bottom sediment and contaminated water ・Treatment for deposited bottom sediment and contaminated water in the sea ・Treatment for sludge and contaminated water from industry disposal ・Treatment for sludge and contaminated water from agriculture ・Treatment for sludge and contaminated water from sewage MSC is an abbreviation for "Miracle Sludge Clean." The main contents of MCS are iron salt and metal salt, and this inorganic flocculant is composed of rare earth elements. MSC method is the general term of "bottom sediment treatment and water purification technology with MSC." As hydrophobing dehydration treatment and soil stabilization additive, MSC facilitates dredge bottom sediment precipitation and consolidation, as well as purifies spill stream. The structure of sludge consists of fine particles which aggregates of mineral particles. Spaces among fine particles filled with water and air, and these soil particles usually have negative charge. By adding MSC there, MSC electrically neutralizes negative charge of soil particles because MSC is positive ion substance. At this time, capillary water combining with soil particles is separated. Then, interstitial water and a film of absorbed water become free water. By this hydrophobing phenomenon, soil particles adsorb each other, and then particle diameter becomes bigger, which leads sedimentation. Moreover when adding polymer flocculant, the diameter of flock gets bigger, and it settles down very fast. This flocculation sedimentation soil has large hydraulic conductivity by a hydrophobing phenomenon of soil particles. Thus, it enables to conduct effective dehydration of bottom sediment and improve dehydration soil easily. The principle

Principal component of MSC is iron salt (mainly ferric chloride) and metal salt (mainly aluminum sulfate), and MSC includes inorganic flocculant which is composed of alkaline rare earth element.

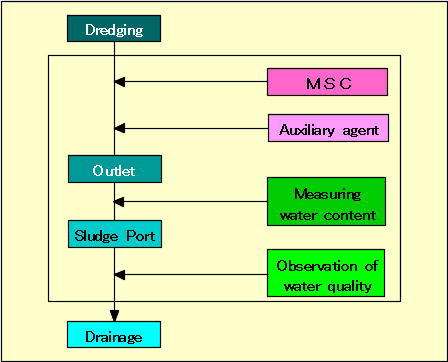

Special feature and effectMSC destroys adsorption water film covering the fine particle's surface in soil particle that composes bottom sediment. It is excellent in hydrophobization that releases a large quantity of free water in the soil particles. Hydrophobic fine particles absorb and combine each other. These particles become granulation and settle down quickly. After settling down, the whole gradually shrink and it exerts consolidation in accordance with increase of sediment volume. Consequently, water around soil particles is separated from soil particles and become pure supernatant water.1. Separated spill stream becomes supernatant water as soil particles agglutinate and settle down quickly. Particularly, the initial settling is fast 2. Increasing in hydrophobization and it is able to have space to store a large quantity of separated soil in treatment places due to large consolidation coefficient 3. We can quickly move to the second construction process because treatment places quickly dry out and coefficient of permeability is large 4. The safety tests proved its harmlessness to surrounding environment 5. Separated soil has effects as compost and soil improvement agents by MSC's component (iron, potassium, calcium) and nutrient salts (nitrogen, phosphorus) in bottom sediment and microorganisms. Thus, the separated soil is reused for agricultural soil 6. Not only hydrophobization of organic mud (sludge), but also MSC has an effect on flocking and settling of toxic substance in the contaminated water The process of bottom sediment

Bottom Sediment treatment with MSC method (SO-EN CO., LTD) Effective utilization of separated soilBottom sediment piles up near closed water area of inland, stagnant river which has slow current, and inner bay, and that is cause of water pollution. For this environmental improvement, the bottom sediment is removed (dredging). Moreover, the dredging is generally conducted for securing storage capacity and for ship navigation.Such dredging has been conducted in many water areas, and that results in a large amount of bottom sediment (dredging soil). To process bottom sediment, there are two disposing ways. One is a disposal to the land, and the other is a disposal to the water. In the current condition, in order to enable to transport dredging soil to the land by truck, we need to consider issues of dehydration and solidification. In addition, there is a issue about deterioration of surrounding environment where the truck goes through. A disposal to the water discards at a water side of reclaimed land. Although a large quantity can be transported at one time by ship, there are various problems such as environmental issues and the way of the reclaimed land's usage. In the future, it is expected that it is hard to secure the place to be reclaimed land. Moreover, it is necessary to effectively use secured reclaimed land. There are a lot of problems with these conventional constructions. One of these ploblems is that the determination of the soil amount throwing into disposal land. This amount is calculated by figuring out bottom sediment soil amount and then just multiplying this amount with increase rate through dredging. Problems of conventional constructions 1. It is hard to decide the amount of acceptable soil for disposal land 2. Because it can not expect self-weight settlement during reclaimed construction, the acceptable soil amount decreases, thus it is not economical 3. As it can not figure out subsidence (soil-weight settlement) after the reclaimed construction, it is hard to expect soil stabilization 4. It needs to be transported and disposal as industrial waste due to using fixation agent of cementitious materials Merits of MSC method 1. It can determine the amount of acceptable soil exactly 2. As it can figure out amount of self-weight settlement, the amount of acceptable soil increases, thus it is economical 3. Strength of consolidation increases after the reclaimed construction. It is not need to consider soil stabilization, thus it is economical 4. Separated soil can recycle because it is rich soil |

| Copy right©JWG All rights reserved. |